Pulp Moulding Production Line

Advantages of SODALTECH Paper Pulp Moulding Machines

- Machines Sophisticated yet easy to operate

- Rust protected solid steel construction

- Fast interchanging of moulds with dryer linking option

- User friendly control panel with low maintenance service system

- Low cost of production due to less power, space and labour

- Choice of end product colors

- Water proof products by using additives

- High and fast return on investment

Range of Moulding Machines Popular In Market

BASIC MODEL EGG TRAY MACHINE :-

- Direct Hot Press

- Low cost of production due to less power, space and labour

- Egg Carton Machine

- Disposable Pulp Tableware Lines

- Dry in Mold Technology

- Dry Type Pulp Mould

- Dry Type System Pulp Moulding

- Finery Pack Line

- Fruit Tray Line Machines for Paper Based Packaging

- Pulp Moulding Production Lines for Industrial Packing

- Tableware Machines

- Tableware Equipments

- Quality Egg Tray Making Plant

- Quality Egg Box Making Machine

- Advanced Pulp Moulding Technology

- Oven Dry Manufacturing Process

- Productive Packing Material

- Male Urinal Bottle Machines

- Dry Type Pulp Moulding Machine

- Disposable Pulp Tableware Production Lines

- Fine Pulp Molding System

- Pulp Male Urine Bottle Moulding Machine

- Pulp Tableware Line

- Tool and Die set Manufacturing

- Wet Type Pulp Moulding Machine

Latest Model Pulp Moulding Machine (Model EPR 5000/AERM – 110K)

Corporate Video

Our Machinery

- EPR 1300 / DPM 1300

- EPR 3000 / AERM 40K

- EPR 5000 / AERM 110K

- Hot Press Machine

- Hydrapulper

- Drier

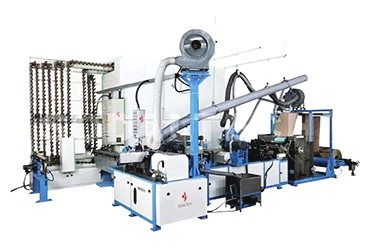

Reciprocating Model – Pulp Moulding Machine

This model is recommended for entry level pulp molding, projects, with medium output. (e.g.: egg trays, fruit trays, etc)

This is similar to the conventional Wet moulding process with transfer mould and forming mould working on reciprocating method. The forming mould goes down to the pulp and comes out as product formed over the mould. The transfer mould comes down, does wet press and goes up by holding the wet product with it.

EPR 3000 Model

The Rotary Model Moulding Machine is of state-of-the-art design and is operated by electro-pneumatic power. The advanced design of control has independent control circuits for all operating units and conveniently located remote control operation ensures the operator to work comfortably and to have close monitoring of the process. Most of the sensitive operations are logic controlled and fail safe.

EPR 5000 Model

This model is highly suitable for high volume production of egg trays, fruit trays etc. This machine is fitted with sophisticated indexing mechanism to ensure optimum performance levels.

Hot Press Machine – HPS 500 Model

This machine is used to add smooth finish and presentation to the trays. The machine is simple to operate and maintain and the output is synchronised with main moulding machine.

Hydrapulper

This machine is used to make pulp from waste paper.

The machine is ruggedly built to withstand fluctuating heavy pulping loads and the walls are made of mild steel with rust preventive coatings. The special material used in cutter (Impeller) ensures aggressive cutting action with less input of power and time. The cutter is operated by an electric motor. Optional Automatic waster paper conveyor can be attached to pulper.

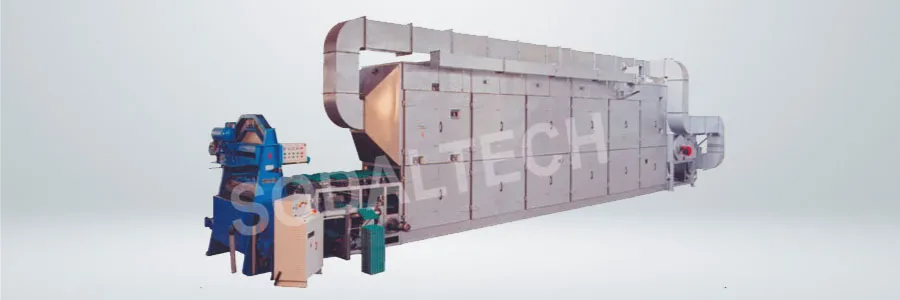

Drier

The On-Line Drier is used to dry the products and delivers out the same through the conveyor. The On-Line Drier is of tunnel type having independent metal trays coated with heat resistant coating and holders operated by automatic indexable conveyorised chain. The conveyor is of multi-pass system to save energy, space and investment. The whole chamber is made in a strong fabricated structure and the walls are insulated to have minimum radiation loss. Both sides of the Drier can be opened easily for general maintenance and inspection. The inner walls and ducts are protected with heat resistant paint for long life. A safety clutch is provided to prevent any major accident while in operation.