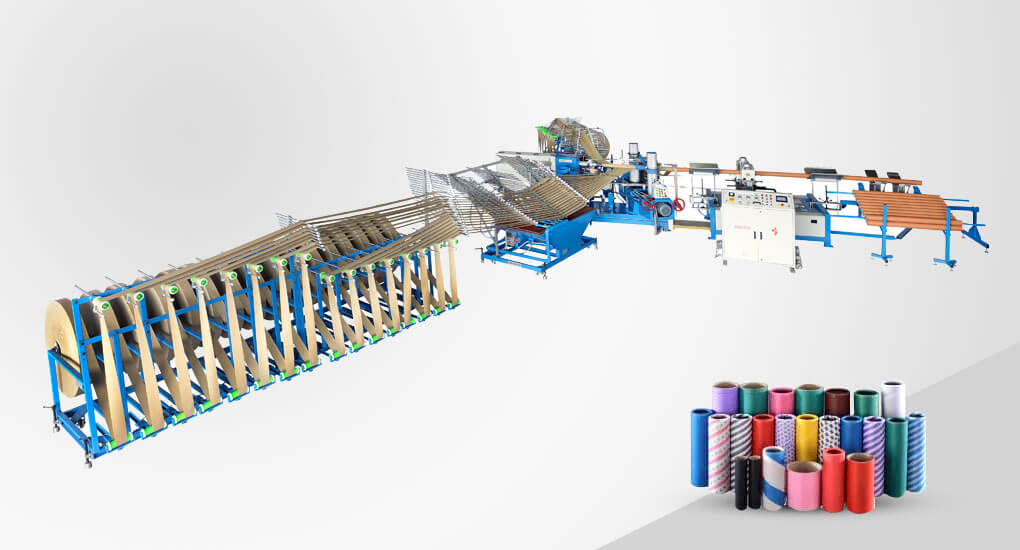

Paper Tube and Core Production Line

Salient Features

- Higher output, Extra strong tubes

- Electronic proportional control system for winding speed adjustment

- Rapidly interchangeable mandrels

- Pneumatic control of winding belt tension

- Built-in control panel with remote station.

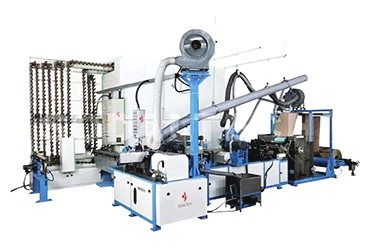

Fully Automatic Textile Tube Making Machine with Automatic Recutter and Finishing Machine

- Easy to operate and maintain

- Easy interchangeability of toolings

- Highly suitable for DTY Tubes production

- Paper Tube Winder

- Paper Core Winder

- Ultra Heavy Duty Model

- Paper Tube Winder with Multi Cutter

- Automatic Tube Finishing Machine

- Automatic Core Cutter SARC Series

- Automatic Core Cutter EC Series

- Convolute Tube Winder

Paper Tube Winder

Paper Tube Winder (CCW MODEL)

This machine is used to manufacture thin, medium walled paper tubes and cores for tissue rolls, fax rolls etc.

Salient Features

- Output : Up to 15 mts/min. depending upon the sizes of the tube

- Minimum inner diameter : 25 mm

- Maximum wall thickness : 5 mm

- Higher output

- Electronic proportional control system for winding speed adjustment

- Rapidly interchangeable mandrels

- Pneumatic control of winding belt tension

- Built-in control panel with remote station

Paper Core Winder

Paper Core Winder

This heavy duty Spiral Paper Core winder is suitable to produce thick walled cores for various applications like paper mill reel cores, film winding cores, carpet cores etc.

This machine is easy to operate and maintain. The cutting carriage moves on free slide rails synchronized with the main tube winder. The online fine cutting unit delivers burr free cores without dust and noise generation.

Salient Features

- Output : Up to 15 mts/min. depending upon the sizes of the tube

- Minimum inner diameter : 30 mm

- Maximum inner diameter : 500 mm

- Maximum wall thickness : 16 mm

- Higher output

- Electronic proportional control system for winding speed adjustment

- Rapidly interchangeable mandrels

- Pneumatic control of winding belt tension

- Built-in control panel with remote station

Ultra Heavy Duty model for Construction Cores

This model is highly suitable for producing larger diameter cores for construction pillars, storage cores etc.

Paper Tube Winder with Multi Cutter

This versatile spiral Paper Tube Winder is to deliver high output of pre-cut cores for toilet tissue winding, kitchen foil winding etc.

Automatic Tube Finishing Machine

This automatic Tube Finishing Machine is suitable for finishing textile yarn carriers like DTY and POY tubes and fitted with automatic tube transfer mechanism.

- Both Ends Polishing

- One end curling & other end polishing

- POY Tube Notching & Grooving

- Easy interchangeability of toolings

- Thread notch depth angles & reference are easily adjustable

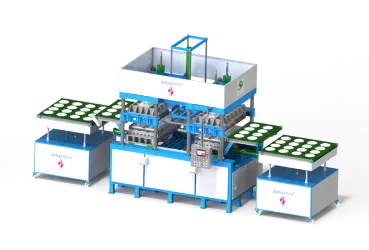

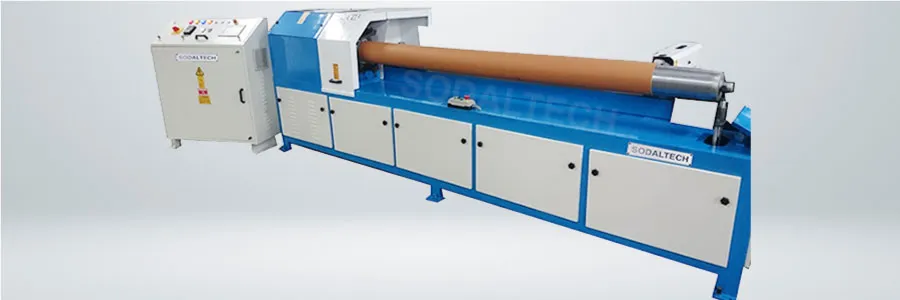

Automatic Core Cutter SARC Series

Salient Features :

Our Automatic Core Cutter is used to re-cut jumbo length cores into smaller size cores.

This machine is very ideal for users of paper cores like Paper Mills, Newsprint mills, BOPP Film manufacturers, converters etc. who can reduce their inventory and hassles of buying cores in different lengths from core manufacturers. They can stock jumbo length cores and cut into required lengths suiting their production plans using this core cutter.

This machine is fitted with suitable safety devices for operator’s protection. The core cutter is simple to operate and maintain.

- Output : Up to 6 cuts per minute depending upon the sizes and widths (or) approx. 6000 jumbo cores / day

- Minimum inner diameter : 50 mm

- Maximum inner diameter : 150 mm

- Minimum length of cut : 50 mm

- Maximum length of cut : 3000 mm

- Maximum wall thickness : 16 mm

Automatic Core Cutter EC Series

AUTOMATIC PAPER CORE CUTTING MACHINE Model EC 1500 to recut jumbo length paper cores into smaller width cores.

Salient Features of the Machine :

Cutting station : Operated by imported SERVO system of reputed brand with programmable length cutting facility (single or six different cutting width) with touch screen operation.

Various cutting options can be easily programmed

Burr free fine cutting

Output : Approx. 20 cuts per minute depending upon the core sizes and cutting width

Operator : One person

Working Range

- Minimum Inner Diameter of Core : 50 mm

- Maximum Inner Diameter of Core : 203 mm

- Maximum wall thickness of Core : 12.5 mm

- Minimum length of Parent Core : 300 mm

- Maximum length of Parent Core : 1500 mm

- Minimum cut length : 15mm

- Maximum cut length : 1500 mm

- Cutting Accuracy : +/- 1 mm depending upon the sizes

- Power (Approx) : 3.5 KW

- Required Air pressure : 6 Bar maximum

AUTOMATIC PAPER CORE CUTTING MACHINE Model EC 2200 (Special model) to recut jumbo length paper cores into smaller width cores.

Salient Features of the Machine :

Cutting station : Operated by imported SERVO system of reputed brand with programmable length cutting facility (single or six different cutting width) with touch screen operation.

Various cutting options can be easily programmed

Burr free fine cutting

Output : Approx. 20 cuts per minute depending upon the core sizes and cutting width

Operator : One person

Working Range

- Minimum Inner Diameter of Core : 50 mm

- Maximum Inner Diameter of Core : 203 mm

- Maximum wall thickness of Core : 16 mm

- Minimum length of Parent Core : 300 mm

- Maximum length of Parent Core : 2300 mm

- Minimum cut length : 15mm

- Maximum cut length : 2200 mm

- Cutting Accuracy : +/- 1 mm depending upon the sizes

- Power (Approx) : 3.5 KW

- Required Air pressure : 6 Bar maximum

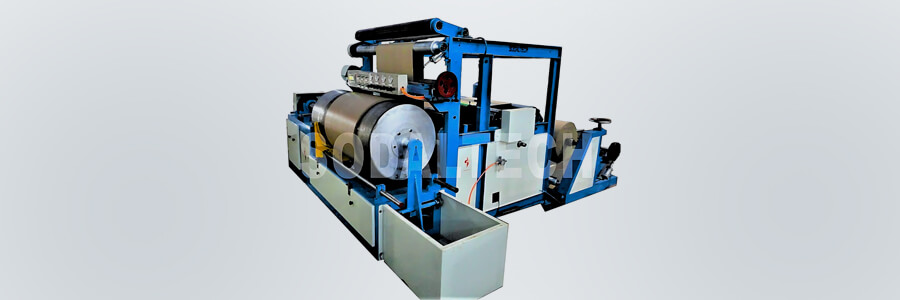

Convolute Tube Winder

SODALTECH Convolute core/Drum winding machine capable to produce convolute wound (parallel winding) paper cores and drums :

- 900+ installations

- 70+ across countries

Technical Specification

- Minimum Width – 300mm

- Maximum Width – 900mm

- Minimum Inner Diameter – 300mm

- Maximum Inner Diameter – 600mm

- Minimum wall thickness – 5mm

- Maximum wall thickness – 25mm

- Output : Upto 300 cycles per day depending upon the size, workers efficiency etc.

- Standard Accessory : Motors, Controls, 1 Mandrel of size 500mm supplied alongwith the machine

Machine fitted with automatic stripping arrangement (end product delivery)

All additional size mandrels and additional size winding belt shall be at extra cost