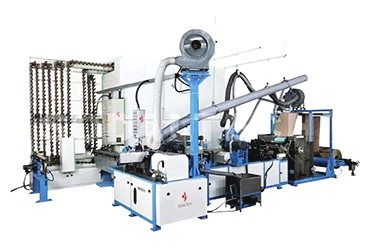

Edge Protector Production Line

The Edge Protector Making Plant is made heavy duty to produce high strength paper edge protectors and U Profile and C Profile channels which are very ideal to prevent damages to edges of various palletized goods and circular goods like paper reels, steel coils etc.

The machine is rugged, yet easy to use. It has facility to interchange profile design and variable speed drive for faster setting and control of process wastage.

The future of packaging lies in the recyclability of most of the packaging materials. Edge protector is an environment-friendly product using strong paper board which is easily recycled.

Salient Features

- Output : Up to 30 meters per minute depending upon the sizes

- Sizes made (ANGLE BOARDS) : 25 X 25, 40 X 40, 50 X 50, 75 X 75, 100 X 100 up to 6mm wall thickness in any standard lengths

Edge Protector Plant with

Servo Driven Online Cutter

Corporate Video

Our Machinery

- Edge Protector Rotary Notching Machine

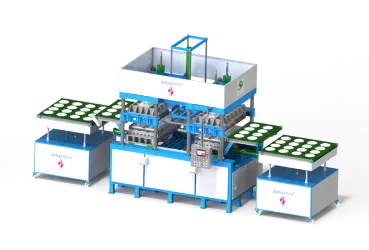

Edge Protector Rotary Notching Machine

SODALTECH EBRN 75 Model Paper Edge Protector Rotary Notching Machine

(Wrap-around cutting) to make continuous V-notching fitted with rotary cutting system with following features :

- Paper Edge Protector size : Minimum 25 x 25 mm, Maximum 75 x 75 mm

- Wall thickness : Minimum 2 mm, Maximum 3 mm. Depending upon size

- Parent Edge Protector length : Minimum 200 mm, Maximum 4000 mm (more length on special order)

- Motor : 1.5 KW (2 HP)

- Production speed : Upto 35 metres / minute depending upon the size

- Thickness adjusting mechanism

- Collection stand for notched edgeboards

- Operator : 1 Person