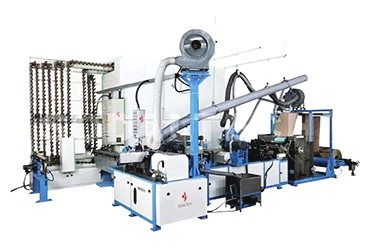

Composite Can Production Line

The Composite Can Making Plant is suitable to make Composite Cans for packaging detergents, liquor bottles, automobile components, engineering goods, laminated cans for packaging potato wafers, fruit drinks, etc. These composite cans are eco-friendly as they are easily disposable and recyclable.

The can body maker is fitted with folding and heat sealing equipment to heat seal the inner aluminum foil layer for leak-proof cans.

The key feature of this production line is its high performance with low maintenance cost. The composite cans making machinery comes with other optional equipment for producing composite cans, which include a labeling machine, can flanger, and can seamer.

The composite can production line facilitates the easy interchangeability of toolings for various sizes of cans.

Salient Features

- Output : 30,000 cans per day of 24 hours operation depending upon the sizes

- Minimum inner diameter of the can : 25 mm

- Maximum inner diameter of the can : 100 mm

- Maximum height of the can : 525 mm

- Maximum Wall thickness : 3 mm

- Composite Can Body Maker

- Heat Sealing System

- Horizontal Labelling Machine

- Automatic Convolute Labelling Machine

- Can Flanging Machine

Composite Can Machine

The main salient feature of this production line is its high performance with low maintenance cost . The composite cans making machinery comes with other optional equipment for producing composite cans. The other major parts of composite can production line include labelling machine, can flanger and can seamer. The composite can production line facilitates easy interchangeability of toolings for various sizes of cans.

Heat Sealing System

This system comes with inner liner folding device with suitable mandrel cooling arrangement.

Horizontal Labelling Machine

Salient Features

- Output : Up to 30 pieces per minute depending upon size and operator’s efficiency (or) approx. 35,000 cans/day depending upon the sizes

- Minimum inner diameter of tube : 50 mm

- Maximum inner diameter of tube : 100 mm

- Maximum wall thickness : 5 mm

- Maximum width of labelling area : 500 mm

Automatic Convolute Labelling Machine

Automatic Convolute Labelling Machine – ACLM 550 MODEL

Salient Features

- Automatic label pick up from operator

- Recut of labelled tubes

- Automatic tube collection at conveyor

- Minimum Inner Diameter : 50mm

- Maximum Inner Diameter : 100mm

- Minimum length : 100mm

- Maximum length : 450mm

- Maximum parent tube length : 500mm

- Maximum labelling area : 475mm

- Label thickness : 120 GSM

- PLC controlled panel with AC drive

- Power (Approx) / Machine : 2 KW

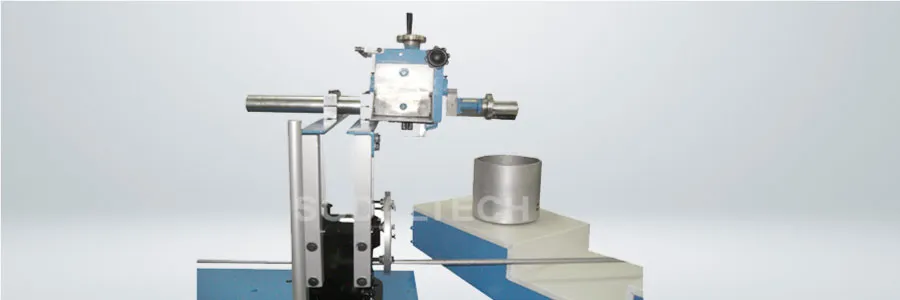

Can Flanging Machine

To make flanging at the ends of the can for firm holding and crimping of the lid.

Salient Features

- Output : 25 cans / minute depending on the operator’s efficiency

- Minimum inner diameter of the can : 22 mm

- Maximum inner diameter of the can : 150 mm

- Maximum height of labelling area : 350 mm