Pulp Moulding Plant

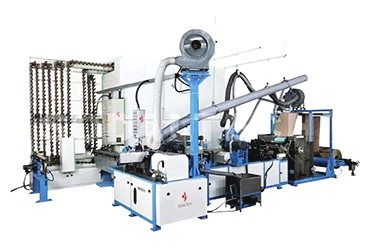

PULP MOULDED EGG TRAY PRODUCTION LINE MODEL EPR 1300

CAPACITY : Upto 1300 pieces (30-cavity egg trays) per hour @100% efficiency

ABSTRACT DETAILS OF PROJECT

1. Pulp Preparation System – 1 Set

2. Service system – 1 set.

3. Reciprocating Moulding Machine with 4 Nos. suction moulds and 4 Nos. transfer moulds -1 No.

4. On-line Conveyorised Drier – 1 No

5. Tray Compacting machine – 1 No

6. Gas Heating system without Gas Burner – 1 No.

300 Sq.Mtrs

Recommended size of factory shed : 25 mtrs length x 12 mtrs width x 5.0 mtrs height

100 Kgs/hour

400 Litres / hour

FUEL USED

(Note : There will be some differences at the site depending on the products

made and local working conditions)

Diesel

(9000 k.cals/litre) : 29 litres / hour (approx.)

Natural Gas

(9500 k.cals/cubic metre) : 27 cubic metres / hour (approx.)

LPG (Liquified Petroleum gas)

11,500 k.cals / kg : 22 kgs / hour (approx.)

5,900 k.cals /litre : 43 litres / hour (approx.)

a) Production Line : 115 HP (87 KW)

b) Air Compressor : …20 HP (15 KW)

(Customer scope) —————————–

Total :……………………. : 135 HP (102 KW)

Three Phase , 380-440 V , AC 50/60 HZ

NOTE

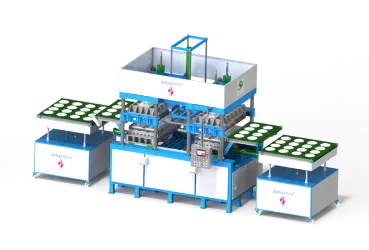

PULP MOULDED EGG TRAY PRODUCTION LINE MODEL EPR 3000

CAPACITY : Upto 3000 pieces (30-cavity egg trays) per hour @100% efficiency

ABSTRACT DETAILS OF PROJECT

1. Pulp Preparation System – 1 Set

2. Service system – 1 set.

3. Multi-Side Rotary Moulding Machine with 16 suction moulds and 4 transfer moulds – 1 No.

4. On-line Conveyorised Drier– 1 No

5. Tray Compacting machine – 2 Nos

6. Gas Heating system without Gas Burner -1 No

800 Sq.Mtrs (Length not less than 40 metres)

Recommended size of factory shed : 40 mtrs length x 20 mtrs width x 5.5 mtrs height

200 Kgs/hour

800 Litres / hour

FUEL USED

(Note : There will be some differences at the site depending on the products

made and local working conditions)

Diesel

(9000 k.cals/litre) : 67 litres / hour (approx.)

Natural Gas

(9500 k.cals/cubic metre) : 62 cubic metres / hour (approx.)

LPG (Liquified Petroleum gas)

11,500 k.cals / kg : 51 kgs / hour (approx.)

5,900 k.cals / litre : 100 litres / hour (approx.)

a) Production Line : 180 HP (135 KW)

b) Air Compressor : ..25 HP (18.75 KW)

(Customer scope) ———————————

Total …………………….. : 205 HP(153.75KW)

Three Phase, 380-440 V, AC 50/60 HZ

NOTE

PULP MOULDED EGG TRAY PRODUCTION LINE MODEL EPR 5000

CAPACITY : Upto 5000 pieces (Standard size 30-cavity egg trays) per hour @100% efficiency. (Maximum product size : Within 295 mm x 295 mm)

ABSTRACT DETAILS OF PROJECT

1.Pulp Preparation System – 1 Set

2.Service system – 1 set.

3. Multi-Side Rotary Moulding Machine with servo Drive with 20 suction moulds and 5 transfer moulds – 1 No. (Maximum product size : within 295 mm x 295 mm)

4. On-line Conveyorised Drier– 1 No

5. Gas Heating system without Gas Burner -1 No

900 Sq.Mtrs (Length not less than 60 metres) Recommended size of factory shed : 60 mtrs length x 15 mtrs width x 5.5 mtrs height

FUEL USED

(Note : There will be some differences at the site depending on the products

made and local working conditions)

Diesel

(9000 k.cals/litre) : 112 litres / hour (approx.)

Natural Gas

(9500 k.cals/cubic metre) : 105 cubic metres / hour (approx.)

LPG (Liquified Petroleum gas)

11,500 k.cals / kg : 87 kgs / hour (approx.)

5,900 k.cals / litre : 170 litres / hour (approx.)

a) Production Line : 244.50 HP (182.5 KW)

b) Air Compressor : …30 …….HP ( 22 KW)

(Customer scope) ———————————–

Total………………………. : 274.50 HP (204.5 KW)

Three Phase , 380-440 V , AC 50/60 HZ

NOTE

Corporate Video

Our Machinery